How an Optical Fibre Diameter Analyser Improves the Performance of Fibre Optic Networks

How an Optical Fibre Diameter Analyser Improves the Performance of Fibre Optic Networks

Blog Article

Comprehending the Performance of an Optical Fibre Diameter Analyser in Modern Production

The optical Fibre Diameter analyser functions as a critical tool in modern manufacturing, offering precise, non-contact dimensions that are crucial for preserving stringent sector requirements. By leveraging innovative laser technology, these analysers not only make certain very little signal loss yet likewise boost the overall efficiency of optical fibers. Their capacity for real-time information processing enables manufacturers to promptly attend to any type of discrepancies from specs, cultivating a culture of constant renovation. Comprehending the details of this modern technology questions regarding its broader implications in making performance and top quality control across various fields.

Relevance of Optical Fibre Dimension

In modern-day production, the measurement of optical Fibre Diameter is vital for guaranteeing the performance and reliability of Fibre optic systems. Exact Diameter measurement straight influences optical performance, as variations can bring about enhanced signal loss, minimized transmission capacity, and diminished overall effectiveness. The optical homes, consisting of light transmission and signal honesty, are very conscious the Fibre's Diameter, necessitating specific control throughout production.

Additionally, standardization in Fibre Diameter is important for compatibility and interoperability within diverse telecoms networks. As these networks broaden around the world, preserving uniformity in Fibre qualities promotes seamless integration across numerous elements and systems. In addition, sticking to sector requirements concerning Diameter resistances is vital for suppliers to meet governing demands and consumer expectations.

Investing in innovative measurement technologies not only boosts manufacturing effectiveness but likewise sustains quality guarantee procedures, allowing makers to recognize problems early in manufacturing. This positive method lowers waste and makes certain that the last items fulfill strict efficiency standards. Subsequently, the value of optical Fibre measurement can not be overemphasized, as it functions as a foundation for high-grade, trusted Fibre optic systems, which are essential to modern-day communication infrastructure.

Exactly How Diameter Analysers Job

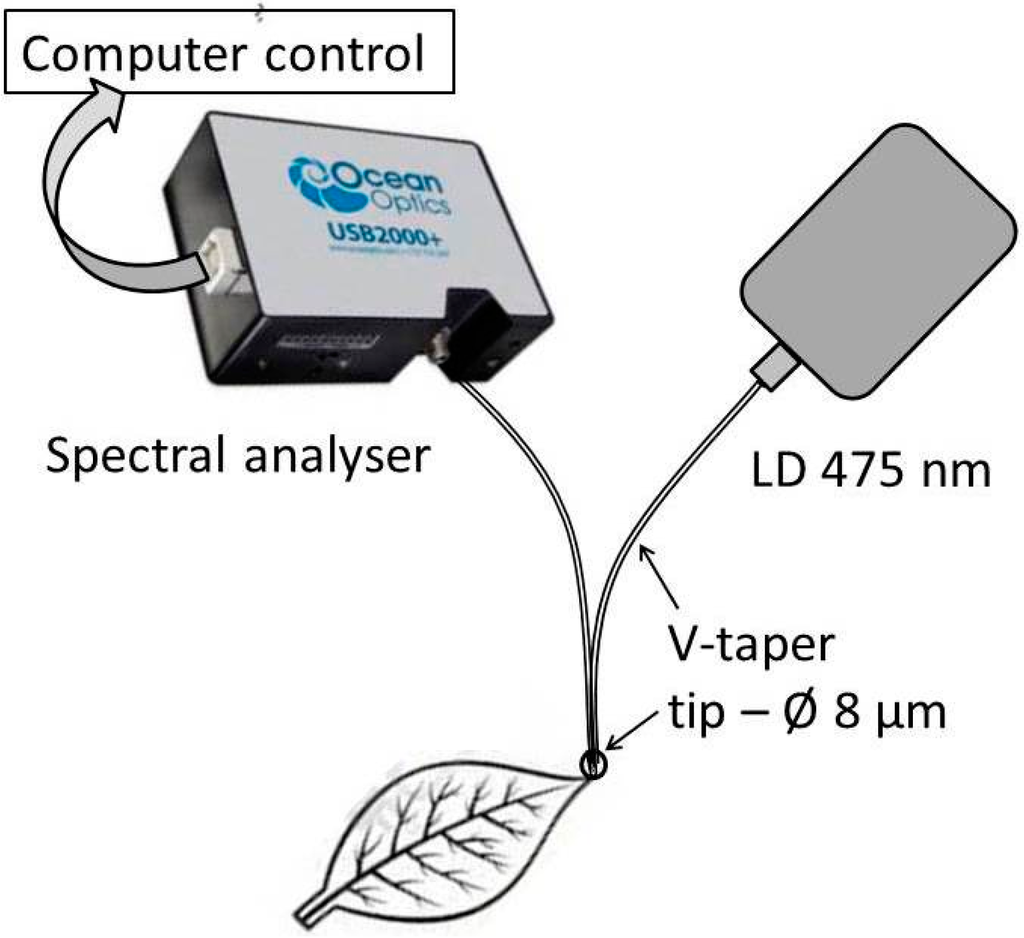

The core operation depends on the concept of light spreading and reflection. As the laser beam of light strikes the Fibre, variants in Diameter cause changes in the light's intensity and wavelength (optical fibre diameter analyser). This data is processed in real-time utilizing innovative formulas that translate the optical signals right into accurate Diameter measurements

In addition, several Diameter analysers are furnished with multiple dimension factors along the Fibre, enabling a comprehensive assessment of Diameter consistency. This is important in making certain that the optical fibres satisfy rigorous sector standards. The whole procedure is automated, making it possible for high-speed measurements and minimizing human error. The implementation of such technology dramatically boosts quality assurance in production, making certain that optical fibres are created to specific specifications for optimal efficiency in their intended applications.

Key Attributes to Think About

When picking an optical Fibre Diameter analyser, a number of key functions call for careful factor to consider to guarantee ideal performance and integrity. Initially, measurement precision is paramount; the analyser must give accurate Diameter analyses, generally in micrometers, to satisfy rigorous manufacturing requirements. Additionally, a vast dimension variety boosts versatility, suiting various Fibre kinds and densities.

One more vital function is the analyser's speed. Rapid measurement abilities enable increased throughput, vital in high-volume manufacturing atmospheres. In addition, real-time information processing and feedback capacities make i thought about this it possible for instant adjustments, boosting high quality control.

User interface and software application compatibility are also considerable considerations. An easy to use interface simplifies procedure, while robust software program assistance promotes information evaluation and assimilation with existing manufacturing systems. The ability to export data in various formats can improve reporting and conformity efforts.

Additionally, durability and maintenance demands should be assessed. An analyser created from premium products will endure the rigours of a production atmosphere, while simplicity of maintenance guarantees durability and lowers downtime. Take into consideration the degree of technical support and training offered by the manufacturer, as this can substantially influence the efficient use of the look at this website analyser in production settings.

Benefits in Production Effectiveness

Enhancing manufacturing performance rests on the integration of sophisticated technologies, such as optical Fibre Diameter analysers. These instruments play an essential role in guaranteeing that optical fibres satisfy strict high quality criteria, which is crucial for optimum performance in numerous applications - optical fibre diameter analyser. By offering real-time measurements of Fibre Diameter, suppliers can swiftly determine and correct discrepancies from specified resistances, consequently decreasing waste and minimizing the danger of faulty products

Moreover, the very early discovery of possible problems causes reduced downtime and upkeep prices, thus optimizing source allocation. Ultimately, the efficiency acquires realized through using optical Fibre Diameter analysers add to an extra affordable manufacturing atmosphere, guaranteeing that companies can supply top notch items while preserving cost-effectiveness and responsiveness to market demands.

Applications Across Industries

The versatility of optical Fibre Diameter analysers prolongs beyond making efficiency, finding applications across different markets that depend on optical Fibre modern technology. In telecommunications, these analysers are important for guaranteeing the optimal performance of Fibre optic wires, straight impacting data transmission rates and network integrity. By properly measuring Fibre sizes, drivers can decrease signal loss and boost overall interaction top go to this web-site quality.

The medical sector likewise benefits significantly from these tools, especially in the development of endoscopic tools and laser therapies. Precise Diameter dimensions are important for creating effective optical fibres that are utilized in minimally intrusive procedures, improving client outcomes via enhanced imaging and treatment abilities.

In aerospace, the analysers play an important duty in the manufacturing of light-weight, high-strength materials, where Fibre optics are incorporated right into structural parts for surveillance and diagnostics. Furthermore, the automotive market employs these devices to make certain the stability of Fibre optic sensors that improve safety and security and efficiency attributes in vehicles.

Conclusion

Finally, the optical Fibre Diameter analyser is crucial for contemporary production, making sure specific measurements that copyright sector criteria. Its innovative laser technology and real-time information processing capacities boost quality assurance and functional performance. By automating the dimension procedure, makers can swiftly detect deviations, thus lessening signal loss and production downtime. The diverse applications across numerous markets highlight the analyser's relevance in advertising constant renovation and data-driven decision-making within the production market (optical fibre diameter analyser).

In modern-day production, the measurement of optical Fibre Diameter is critical for ensuring the performance and integrity of Fibre optic systems. The relevance of optical Fibre dimension can not be overstated, as it offers as a foundation for top quality, trusted Fibre optic systems, which are essential to contemporary communication framework.

Diameter analysers employ innovative optical technologies to properly determine the Diameter of optical fibres.Additionally, many Diameter analysers are geared up with numerous measurement factors along the Fibre, enabling for an extensive assessment of Diameter consistency.The adaptability of optical Fibre Diameter analysers expands beyond making efficiency, locating applications across various industries that rely on optical Fibre innovation.

Report this page